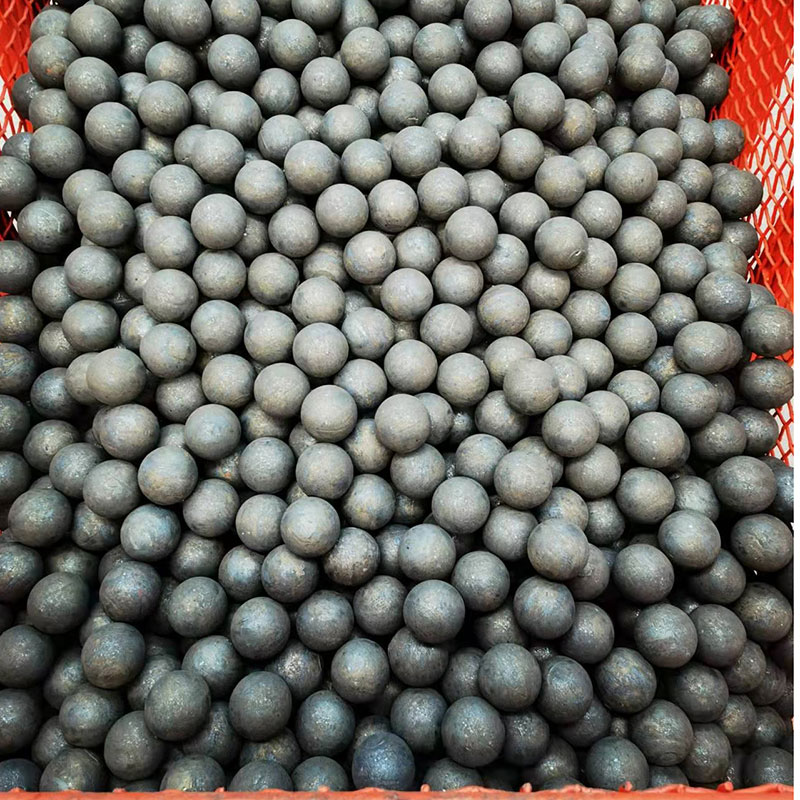

ZWell Grinding Balls for Metal Ore Grinding

Basic Information

ZWell is a Jianlong Group wholly-owned grinding balls manufacturer supplying wide range sizes of grinding balls for clients all over the world.

Grinding balls are an essential mechanical component in ball mill and SAG, used for ore crushing and grinding, thus in preparation for the recovery of valuable minerals.Grinding balls have wide range of applications, including metals, non-metallic, building materials, chemical industries and so on.

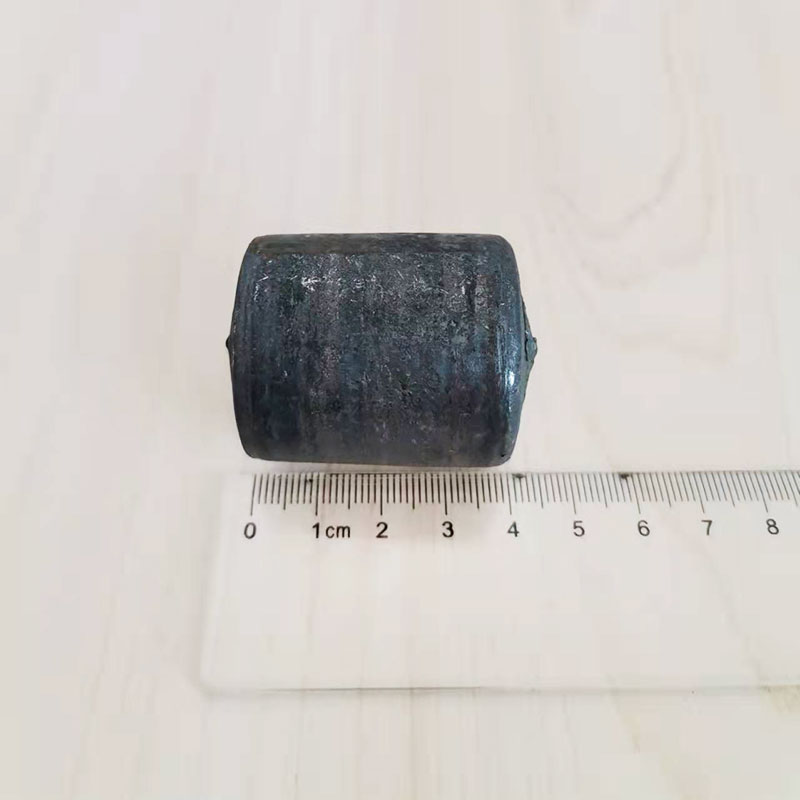

The main parameters of the grinding ball include size, tolerance, weight, chemical composition, hardness, micro-structure, impact toughness, and the times of drop testing. These factors determine the execution efficiency and economy of the ball grinding task. Therefore, in the design and execution of the steel ball production process, it must be carefully considered to ensure the wear resistance of the balls. Because the small process design deviation, or small defects in performance or quality, will have an impact on the wear resistance of grinding ball and the grinding cost.

Relying on the advantages of Jianlong Group high-quality grinding steel R&D and production, according Jianlong Group’s own grinding data and different metal ore grinding condition, ZWell has improved the manufacturing, performance, quality and price of steel balls, and produced steel grinding balls specially for the field of metal ore grinding.The grinding balls can meet the requirements of different types of metal ores grinding process, especially for iron ore, gold ore, copper ore, lead-zinc ore, silver ore and other metal ores.

ZWell provides a variety of ginding ball sizes and types for metal mining, as well as the grinding solutions suitable for different metal ores, to help clines save energy, reduce cost and increase efficiency.

For more details of grinding balls for metal ore grinding, please contact ZWell now.

Product Features

- high and uniform hardness

- greater wear resistance and fatigue endurance

- smooth surface and low circle loss rate

- low breakage rate

Packing