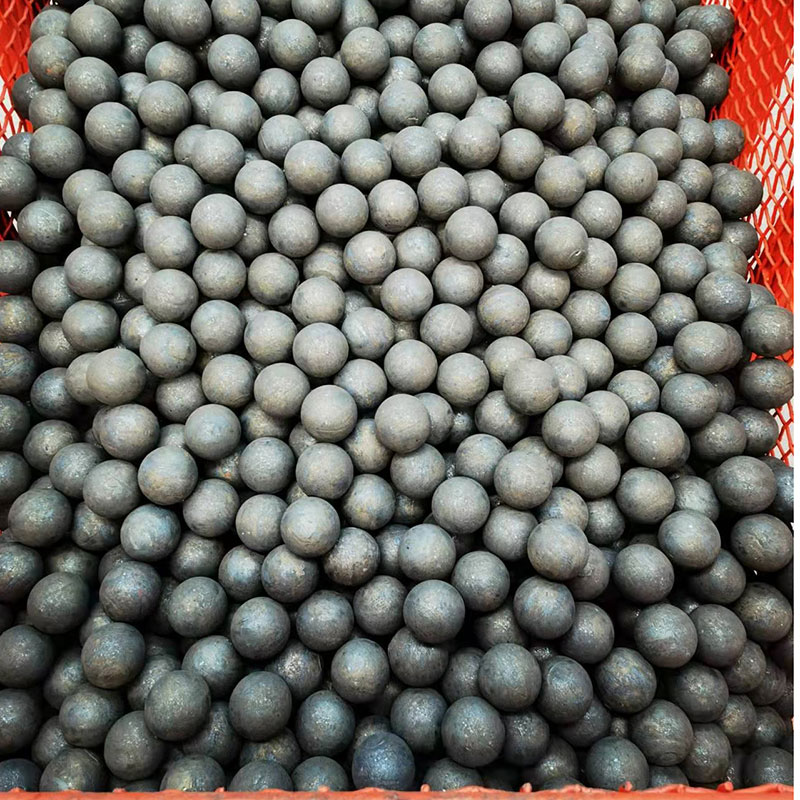

ZWQ Forged Steel Balls for Ball Mills

Property Index

- Volume Density:7.80-7.85g/cm³

- Surface Hardness HRC:≥60

- Core hardness HRC:≥58

- Impact Value Ak:≥12J/㎝²

- Drop Testing:(test per batch)

- height 10m ≥10000times

Product Features

- high and uniform hardness

- greater wear resistance and fatigue endurance

- smooth surface and low circle loss rate

- low breakage rate

Chemical Composition

| Grade | C | Si | Mn | P ≤ | S ≤ | Cr | Ni ≤ | Cu ≤ |

| ZWQ-2 | 0.72-0.86 | 0.15-0.37 | 0.70-0.80 | 0.035 | 0.035 | 0.20-0.65 | 0.25 | 0.25 |

| ZWQ-3 | 0.58-0.66 | 1.30-1.90 | 0.40-0.80 | 0.035 | 0.035 | 0.70-0.90 | 0.25 | 0.25 |

| ZWQ-4 | 0.70-0.90 | 1.20-1.40 | 0.50-0.80 | 0.035 | 0.035 | 0.70-1.00 | 0.25 | 0.25 |

| ZWQ-3-2 | 0.70-0.80 | 1.30-1.40 | 0.70-0.80 | 0.035 | 0.035 | 0.70-0.90 | 0.25 | 0.25 |

Technical Specification

| nch | Size (mm) |

Theoretical Weight(Kg) | Actual Size Range(mm) | Texture Of Material | Surface Hardness | Core Hardness | Volume Hardness |

| (HRC+/-0.5HRC | (HRC+/-0.5HRC | (HRC+/-0.5HRC | |||||

| 1” | Φ25 | 0.075+/-0.01 | Φ24.5~27.5 | ZWQ-2 | 63-66 | 62-64 | 63-66 |

| 1 1/4” | Φ30 | 0.14+/-0.02 | Φ29.7~32.7 | ZWQ-2 | 63-66 | 62-64 | 63-66 |

| 1 1/2” | Φ40 | 0.31+/-0.04 | Φ39.6~43.6 | ZWQ-2 | 63-66 | 62-64 | 63-66 |

| 2” | Φ50 | 0.59+/-0.05 | Φ50~54 | ZWQ-2 | 62-65 | 61-63.5 | 62-65 |

| 2 1/2” | Φ60 | 1.0+/-0.05 | Φ60.4~64.4 | ZWQ-2 | 62-65 | 59-64 | 61-64 |

| 3” | Φ80(75) | 1.9+/-0.1 | Φ76~81 | ZWQ-2 | 61-63 | 59-62 | 60-63 |

| 3 1/2” | Φ90MM | 3.1+/-0.15 | Φ88~93.5 | ZWQ-3 | 60-62 | 58-61 | 59-62 |

Why Choose Us

Tangshan ZWell Equipment Manufacturing Co., Ltd. is Jianlong Group’s wholly-owned steel mills with designed annual capacity of 400,000mts of grinding material. Located in Tangshan, Hebei, China, using Jianlong Beiman high quality grinding steel round bars as raw material, ZWell now can supply 100,000mts of forged grinding steel ball, cylpeb and grinding bars to customers at home and abroad like CHINA GOLD.

Jianlong Beiman Steel Bars as Raw Material

Using Chengde Jianlong and Jianlong Beiman’s mining steel , which has been recognized by international customers

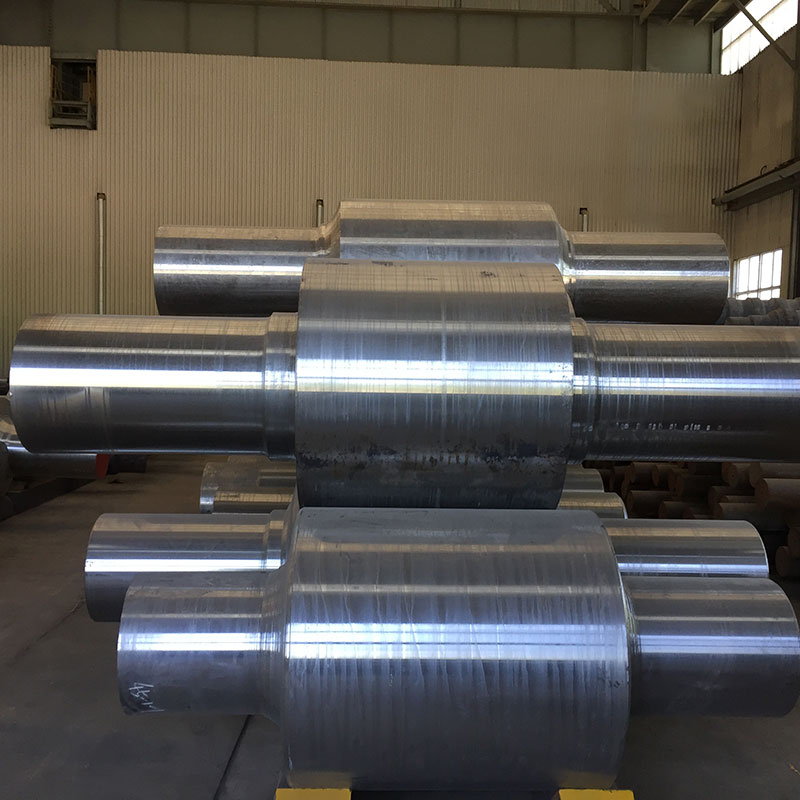

Advanced Production Lines

1.Advanced production lines with high production efficiency ensures the timeliness of supply

2.Whole processes intelligent temperature control monitoring ensures the stability of hardness and toughness, loss of circle rate ≤1%, breakage rate ≤1%

CNAS

1.CNAS Testing Centre and advanced testing instruments( lab certificate no.CNASL14153)

2.Drop test ≥10000times (10m)

Packing